How can FORTA work for Engineers?

Trust in FORTA. Today. And down the road.

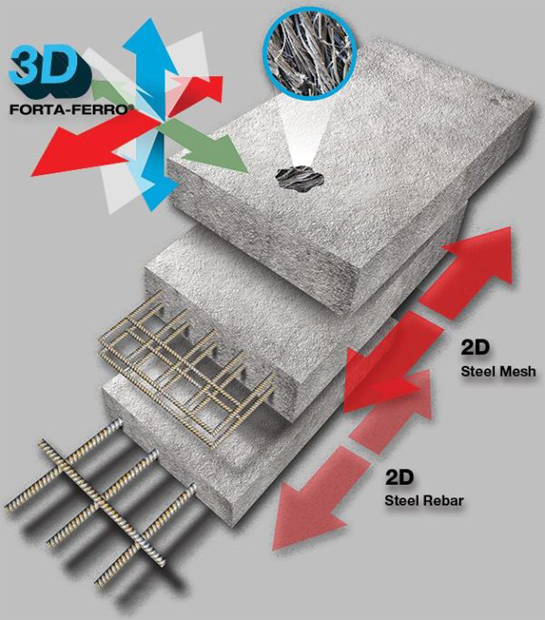

3 Dimensional Reinforcement

BENEFITS OF CHOOSING FORTA-FERRO®

- 3 Dimensional Reinforcement

- Reduction of Plastic and Hardened Concrete Shrinkage Cracking

- Improvement to Concrete Toughness & Long-Term Durability

- Improves Impact & Shatter Resistance

- Enhances Fatigue & Residual Strength

- Overall Project Cost-Savings vs. Conventional Labor-Intensive Steel Reinforcement

- Non-Corrosive and Non-Magnetic

Design & Conversion Services

Our Fiber Experts are here to help you with every step of the process. By filling out the forms below, you will received a detailed report to help with any design or dosage questions you have for your project. All information is kept confidential.

Literature

Learn about the reinforcement options for slab-on-ground applications, and what these options will and will not do

Read about a field test of a concrete warehouse floor whose goal was to find a better way to reduce long-term curling and shrinkage.

FORTA Synthetic Fiber Reinforcement Material Certification

Which Fiber Should I Use?

MICRO MONOFILAMENT

- Reduce plastic shrinkage cracking

- Used in conjunction with steel

- Fine monofilament fiber

- Polypropylene or nylon

- 1.0 lb./cubic yard

- 1/2″ and 3/4″ lengths

MICRO FIBRILLATED

- Reduce plastic shrinkage cracking and temperature-related cracking

- Some light steel replacement

- Fibrillated-net fiber

- Polypropylene

- 1.5 to 3.0 lbs./cubic yard

- 3/4″ and 1-1/2″ lengths

MACRO SYNTHETIC FIBERS

- Reduce plastic and hardened concrete shrinkage & temperature-related cracking

- Add toughness and increase post-crack behavior

- Higher level of steel replacement

- Heavy-duty macrofilament and fibrillated blend

- Polypropylene/co-polymer blend

- 3.0 to 7.5 lbs./cubic yard or higer

- 1-1/2″ and 2-1/4″ lengths

Frequently Asked Questions

What are the benefits of using FORTA-FERRO fiber?

FORTA-FERRO’s twisted bundle technology assures you have the best mixing fiber available, allowing for easy mixing in nearly all concrete mix designs. FORTA-FERRO is an industry-recognized reinforcement alternative for steel. It has been used to replace steel in all aspects of concrete design, from precast applications to slab-on-ground, and everything in between. FORTA-FERRO is very economical to use, both from the initial cost standpoint as well as the reduction in time and labor costs. The dosage can be adjusted up or down for application purposes, depending on the needs of the customer and the expected results of the specific application. FORTA-FERRO is produced in mixer ready bags that are simply thrown into the concrete mixer system and mixed for five minutes. Quite simply, FORTA-FERRO is “Strong as Steel” and twice as easy to use!

What are macro synthetic fibers and how do they differ?

Macro synthetic fibers are the latest advancement in fiber technology, and have been in existence for over 10 years. The shape and collation of FORTA-FERRO allows for the introduction of much higher quantities of longer length fibers into the concrete. Depending on the manufacturer, macro synthetic fibers are produced in many different shapes, sizes and collation methods. Each different combination results in varying levels of performance and user-friendliness. In accordance with first generation synthetic fibers practices, the length and quantity of macro synthetic fibers should be maximized. For best results, FORTA recommends a fiber length of 2.25” and a dosage rate of 3.0-7.5 lbs/yd3.

What is the benefit to using fiber reinforcement rather than steel reinforcement in concrete?

Traditional steel rebar or wire mesh has only one application in concrete slabs: to hold cracked concrete together. Steel is typically supposed to be placed in the center of the slab but is rarely positioned properly. FORTA-FERRO is three-dimensional, increases impact resistance, freeze/thaw durability endurance and overall toughness of the concrete. The instant a crack occurs, there are fibers working to keep the micro crack from becoming a macro crack. This fiber is non-corrosive, non-conductive, safe and easy to use, and faster to install. Simply throw the fiber into the concrete mixer system and mix for five minutes.

Will joints or saw cuts help to reduce cracks and curling?

Joints or saw cuts are simply pre-determined cracks, used to relieve stresses from shrinkage and curling. The edges of each crack are still likely to curl upward and inward. Constant traffic from material handling equipment over these joints and saw cuts will lead to further concrete deterioration, resulting in expensive surface and equipment repairs and ultimately, loss of production.

Can synthetic fibers replace light gauge wire mesh in concrete?

Synthetic fibers have been used to replace light gauge wire mesh in the U.S. for over 32 years. It is important to use a fibrillated “net-like” fiber, which is deformed sufficiently to create anchor points in the concrete and works to hold the cracked concrete together. Materials used to produce the fiber should not absorb water or breakdown in the alkalinity of concrete. For best results, the fiber should consist of polypropylene, and the maximum length and quantity of fiber should be utilized. FORTA recommends a fiber length of 1.5” and a dosage rate of 1.5 lbs/yd3.

How can we reduce plastic shrinkage cracks in concrete?

Shrinkage cracks occur when the surface of the concrete dries faster than the concrete can cure. Cracks can be reduced by adding a fiber to reduce the rapid moisture loss at the concrete surface. In the past, fibers such as grass, straw or animal hairs were used to accomplish this. Advances in technology have allowed for the use of synthetic fibers in concrete to reduce shrinkage cracking at a much higher rate. FORTA is the pioneer of synthetic fiber technology, with over 32 years of innovation and success in producing fibers that will reduce shrinkage cracking.

What characteristics should I look for when choosing a fiber?

The characteristics of a synthetic fiber can be divided into four categories: the shape of the fiber, chemical makeup, recommended dosage and optimum length. Different combinations of these characteristics will produce varying levels of performance. FORTA’s fiber options include monofilament, fibrillated and macro synthetic fibers.

Proven Results

FORTA-FERRO – Tougher & Longer-Lasting Concrete

FORTA-FERRO is an easy-to-finish, color blended fiber, made of 100% virgin copolymer/ polypropylene consisting of a twisted bundle non-fibrillating monofilament and a fibrillating network fiber, yielding a high-performance concrete reinforcement system.

FORTA-FERRO is used to reduce plastic and hardened concrete shrinkage, improve impact strength, and increase fatigue resistance and concrete toughness. This extra heavy-duty fiber offers maximum long-term durability, structural enhancements, and effective secondary/temperature crack control by incorporating a truly unique synergistic fiber system of long length design. FORTA-FERRO is non-corrosive, non-magnetic, and 100% alkali proof!

Preferred Contractors

FORTA’s Preferred Contractors give owners a comfort level that their macro fiber project will be placed and finished properly, making for a visually appealing and impressive final product. FORTA is proud of their affiliation with these established firms, who are acknowledged as leaders in their field and rank amongst the best concrete contractors in the business.